Research News

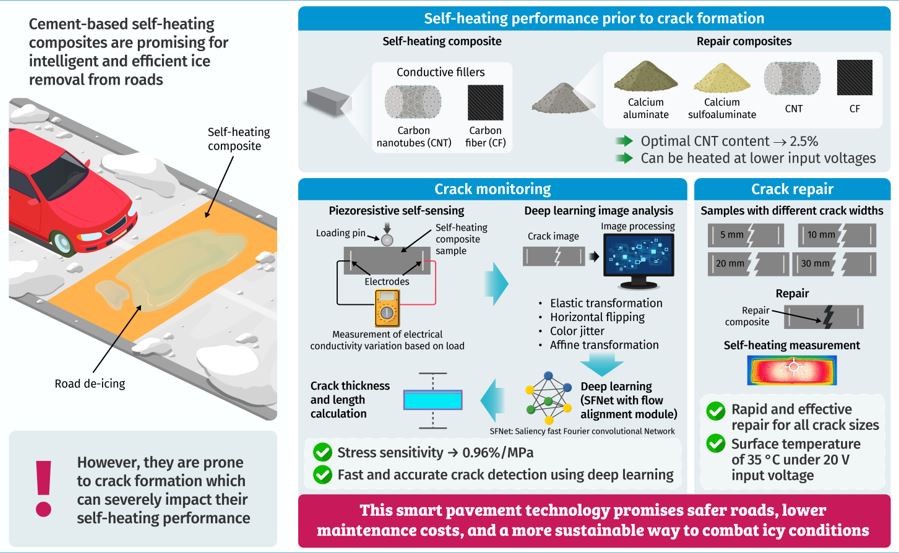

Image title: Proposed approach for real-time crack detection and repair of self-heating composites

Image caption: The real-time crack detection method leverages the self-sensing capabilities of self-heating composites and deep-learning image analysis. The study also presents a new repair material, made up of calcium aluminate, calcium sulfoaluminate, and carbon nanotubes for rapid repair, ensuring continued functionality and extending the lifespan of the composite.

Image credit: Beomjoo Yang from Chungbuk National University

License type: Original Content

Usage restrictions: Cannot be reused without permission

Smart Self-Heating Roads: Innovative Crack Detection and Rapid Repair for Safer Winters

Researchers have developed a new method for real-time crack detection in self-heating roads and their rapid repair using novel repair materials

Traditional methods for removing snow from roads require significant resources and are not suitable for rapid and timely response. While self-heating cement-composites offer a promising de-icing solution, their performance is affected by cracking, a common issue for highways and airport runways. To address this, researchers have developed an innovative method for real-time crack detection and rapid repair of these composites. This breakthrough enhances road safety, reduces maintenance costs, and is more sustainable than conventional methods.

In countries that receive snowfall in winter, ice and snow accumulate on cement-based roads. This creates significant public safety risks, as snow-covered roads reduce traction between vehicle wheels and the pavement, increasing the likelihood of vehicles slipping, which can lead to traffic accidents and aircraft delays. Traditional snow removal methods, such as manual labor and salting, demand significant resources and are not equipped for active and rapid response. Recently, self-heating cement-based composites have emerged as an innovative road de-icing solution to tackle these challenges.

Self-heating composites are made from electrically conductive cement, incorporating conductive filler materials. When electricity flows through the conductive networks within these composites, it gets converted into heat, which helps melt the accumulated snow. These materials can be used for effective and timely de-icing of highways and airport runways. However, these surfaces endure continuous heavy traffic and extreme cold, making them prone to cracking. Cracks can cause breaks in the conductive networks within these composites, reducing their self-heating performance.

To address this issue, a research team, led by Associate Professor Beomjoo Yang from the School of Civil Engineering at Chungbuk National University, Republic of Korea, has developed an innovative approach for real-time crack detection and rapid repair of self-heating composites. “Our technology utilizes the composites’ self-sensing capabilities for real-time crack detection. This is complemented by a deep-learning-based image analysis technique that offers detailed crack information,” explains Prof. Yang. “We have also developed a new repair material that facilitates rapid repair of these composites.” Their study was made available online on January 05, 2025, and published in Volume 293 of the journal Composites Part B: Engineering on March 15, 2025.

In the study, the researchers first tested the self-heating performance of ordinary portland cement (OPC)-based composites incorporating carbon nanotubes (CNT) and carbon fiber as conductive fillers, to establish a baseline reference. Next, they developed the repair composites by utilizing a combination of calcium aluminate cement (CAC) and calcium sulfoaluminate (CSA) cement, with CNT as conductive fillers. Previous studies have shown that CAC and CSA react faster with water than OPC, leading to quicker concrete formation, and have substantially lower carbon dioxide emissions during production compared to conventional OPC. To match the self-heating performance of OPC composites, the optimal CNT concentration was determined to be 2.5% by weight.

Their innovative crack detection method uses the self-sensing properties of self-heating composites. When the distance between conductive fillers in the structure of these composites varies, for example, due to bending caused by loads, their electrical resistance changes. This change in electrical resistance due to external loads, known as piezoresistive sensing, can then be detected for real-time crack monitoring. Additionally, since the bending of cement materials depends on the applied load, this method also enables real-time load monitoring. The self-heating composites demonstrated impressive stress sensitivity of 0.96%/Megapascal, significantly higher than values reported in previous studies.

Beyond electrical resistance monitoring, the researchers also developed a deep-learning-based approach for more detailed crack assessment. This method analyzes multiple images of the cracked cement-composites taken from different angles, using various image processing techniques to provide accurate crack information, including its width and depth.

In experiments, the crack monitoring method successfully detected formation of cracks and offered detailed crack information while the developed repair composites rapidly and effectively repaired the cracks. Moreover, the repair methods successfully restored the self-heating performance of the composites with cracks up to 30 millimeters in size.

“Our research offers a practical solution for maintaining smart infrastructure that also reduces maintenance costs,” says Prof. Yang. “The proposed crack detection and repair system will lead to safer and more resilient road infrastructure, especially in regions affected by harsh winters, while also being more sustainable than traditional de-icing methods.”

Overall, this innovative road de-icing solution not only enhances road safety but also extends the lifespan of roads, while reducing maintenance costs and environmental impact.

Reference

Title of original paper: Novel approach for crack detections and rapid repairment methods in cement-based self-heating composites for smart infrastructures

Journal: Composites Part B: Engineering

DOI: 10.1016/j.compositesb.2025.112126

About the institute

Chungbuk National University (CBNU) is one of the ten Flagship Korean National Universities, a term for institutions in South Korea united under the "Presidential Council of the Korean Flagship National Universities." Since its establishment on September 27, 1951, Chungbuk National University has grown to include 13 Colleges and 8 Graduate Schools. In 1999, CBNU achieved recognition as part of the Brain Korea 21 Initiative by the Ministry of Education. Additionally, in 2003, the university was honored as the top institution in the project fostering regional universities by the Ministry.

Website: https://www.cbnu.ac.kr/english/index.do

About the author

Beomjoo Yang is an Associate Professor in the School of Civil Engineering at Chungbuk National University, Republic of Korea. In 2015, he received his Ph.D. in Civil and Environmental Engineering from KAIST. Before joining Chungbuk National University, he worked as a senior researcher at the Structural Composite Materials Research Center, KIST Institute of Advanced Composite Materials. He has published over 100 articles that have received over 2100 citations. His research focuses on the functionality of construction materials and their analysis, as well as structural material simulation and theoretical modeling.